Product Description:

Our Thermal Spray Powders are specially formulated to provide exceptional Corrosive Wear Resistance, making them ideal for applications requiring durability and protection against corrosive wear. With a Typical Hardness ranging from 1400 to 1700 HV0.1, these powders offer superior strength and resistance to wear and tear.

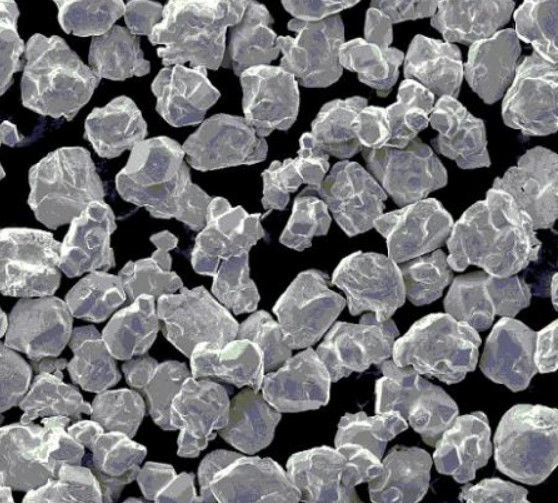

When applied as coatings, our Thermal Spray Powders can achieve Coating Thicknesses ranging from 20 to 500 Microns, providing a reliable barrier against harsh environmental conditions and mechanical stresses. The irregular Shape of the particles ensures a uniform and dense coating, enhancing the overall performance and longevity of the coated surface.

Our Thermal Spray Powders are composed of premium Coating Materials such as WC-CO-CR, WC-10Co-4Cr, and HVAF WC-CO-CR, known for their exceptional hardness and wear resistance properties. With a Hardness level ranging from 500 to 2000 HV, these powders can effectively protect surfaces from abrasive wear, erosion, and corrosion, extending the lifespan of the coated components.

Whether used for industrial equipment, automotive parts, or other high-wear applications, our Thermal Spray Powders offer a reliable solution for enhancing the durability and performance of various surfaces. The combination of high hardness, corrosive wear resistance, and precise coating thickness makes these powders a preferred choice for demanding environments where reliability and longevity are paramount.

Invest in our Thermal Spray Powders today to experience the superior protection and durability they provide. With a proven track record of performance and reliability, these powders are trusted by industries worldwide for their exceptional wear resistance and coating quality.

Features:

-

Product Name: Thermal Spray Powders

-

Chemical Composition: Metallic Or Ceramic

-

Color: Dark-gray Powder

-

Chemicals: Ni 17.5-22% C 7.5-10% Cr Balanced

-

Apparent Density: 2.9 – 5.8 G/cm3

-

Corrosion Resistance: Excellent

Technical Parameters:

|

Chemical Composition

|

Metallic Or Ceramic

|

|

Chemicals

|

Ni 17.5-22% C 7.5-10% Cr Balanced

|

|

Porosity

|

1-5%

|

|

Corrosion Resistance

|

Excellent

|

|

Typical Hardness

|

1400-1700 HV0.1

|

|

Hardness

|

500-2000 HV

|

|

Corrosive Wear Resistance

|

Corrosive Wear Resistance

|

|

Morphology

|

Angular / Blocky

|

|

Apparent Density

|

2.9 – 5.8 G/cm3

|

|

Chemistry

|

WC 12Ni

|

Applications:

BODA Thermal Spray Powders, model Fine Size WC-10Co-4Cr, are versatile coating materials designed for a wide range of product application occasions and scenarios. With ISO9001:2015 certification, these powders provide exceptional quality and reliability for various industrial needs.

The minimum order quantity for the Thermal Spray Powder WC-10Co-4Cr is 50kgs, with a price range of $60-65 per kg. Each order is carefully packaged in 50kg drums and has a delivery time of 7-10 days. Payment terms are open to negotiation, ensuring flexibility for customers.

With a supply ability of 10 tons per month, BODA ensures a consistent and reliable source of Thermal Spray Powder WC-10Co-4Cr for your business needs. The powder exhibits excellent corrosion resistance, making it ideal for applications in challenging environments.

Boasting an apparent density ranging from 2.9 to 5.8 g/cm3, this dark-gray powder offers superior hardness levels between 500-2000 HV. The chemistry of WC 12Ni provides added strength and durability to coatings, ensuring long-lasting performance.

Thermal Spray Powder WC-10Co-4Cr is particularly suitable for industries requiring WC-CO-CR materials for their coating applications. Whether in aerospace, automotive, or energy sectors, these powders deliver exceptional results in protecting and enhancing the performance of various components.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!